僅供個(ge)人參考(kao)

鄂式閘(zha)門适用(yong)于堆比(bǐ)重≤2.5t/m3的各(gè)類礦石(shí)、煤炭、焦(jiao)炭、灰渣(zhā)、化工産(chǎn)品等散(sàn)狀物料(liào),廣泛應(ying)用于建(jian)材、冶金(jin)、化🌏工、玻(bo)璃等行(háng)業的倉(cang)🔆底卸料(liào)。

結構特(te)點:

Structure characteristic:

鄂式(shì)閘門采(cǎi)用優質(zhì)碳鋼焊(han)接成形(xing),結構獨(dú)特,運行(hang)靈活可(ke)⭐靠📐,無卡(kǎ)阻現象(xiang)。配用不(bú)同的傳(chuan)動裝置(zhi)能滿足(zu)不同的(de)工況需(xu)要。電動(dong)♻️鄂式閘(zha)門采用(yong)帶有超(chāo)載🈲保護(hù)裝置的(de)電動推(tuī)杆,可避(bì)免燒壞(huài)電機,可(ke)以遠距(ju)離操縱(zòng)或程序(xù)控制,往(wang)複行程(chéng)可以精(jing)确調節(jiē)位置自(zi)鎖。電液(yè)動鄂式(shì)閘門采(cai)用電液(ye)推杆,全(quan)液壓傳(chuan)動🈲,推拉(lā)力均可(ke)實✏️現無(wú)級調速(su)。氣動鄂(è)式閘門(men)采🧑🏾🤝🧑🏼用氣(qì)🤟動推杆(gǎn),通過配(pèi)件組合(he)可以遠(yuan)距離操(cao)縱或現(xian)場控制(zhì)。SEF為手動(dòng),DEF為電動(dòng),YEF為🈲電液(ye)動,QEF為氣(qi)動。

The valve is welded in fine steel, having the features of peculiar structure, non-obstruction, reliable and flexible operation. It can meet different working condition equipped with different transmission devices. The electric draw stem is equipped with overload protector, which can avoid damage of motor. Program or remote handling can control the electric jaw valve. Reciprocating stroke can adjust position self-locking precisely. The electric hydraulic jaw valve adopts electric hydraulic draw stem and full hydraulic transmission. Thrust and pull can realize stepless velocity modulation. Pneumatic jaw valve adopts pneumatic draw stem and it can control remotely or in local equipped with fittings grouping. SEF denotes manual, DEF denotes electric, YEF denotes electric hydraulic and QEF denotes pneumatic driving.

性能(neng)參數:

Performance parameter:

Suitable temperature | Conglomeration specific gravity | 适用(yòng)介質 |

≤300℃ | ≤ | Crystal, coal, coke, dust slag, chemical product and all kinds of ore |

Transmission device parameters:

規 格 Type | 200 | 300~400 | 500600 | ~800 | 900~1000 |

閘門适(shi)合負荷(hé)(Kg) Suitable loading | 89 | 185240 | ~2950 | ||

電動(dòng)推杆 Electric draw stem | P:0.37KW | DTⅠA500M P:0.75KW | ⅠA700M :0.75KW | DTⅠA1000M :1.1KW | DTⅡA1600M |

DYT300 P:0.37KW | DYT450 P:0.55KW | DYT700 :0.75KW | :1.1KW | DYT1500 P: | |

氣(qì)動推杆(gan) Pneumatic draw stem | 10A-5V CA 80B | 10A-5V CA 100B | 10A-5V CA 125B | 10A-2-5V CA 200B |

Appearance joint dimensions:

B×B | C×C | b | F | n-d | H | M | Ф | |||

× | ×245 | 280×280 | 6 | 350 | 8-Φ12 | 280 | 260 | 320 | 26 | |

300×300 | 355×355 | 400×400 | 8 | 100 | 400 | 12-Φ12 | 300 | 260 | 320 | 26 |

400×400 | 455× | 500×500 | 8 | 120 | 360 | 260 | 320 | 26 | ||

500×500 | 600×600 | 10 | 150 | 510 | 20-Φ14 | 480 | 320 | |||

×600 | 655×655 | 700×700 | 10 | 180 | 560 | Φ14 | 260 | 320 | 26 | |

700×700 | 12 | 220 | 20-14 | 420 | 360 | 32 | ||||

800×800 | 855×855 | 900×900 | 24-Φ14 | 760 | 420 | 32 | ||||

900× | 955×955 | 1000×1000 | 14 | 280 | 720 | 24-Φ14 | 900 | 360 | 32 | |

1000×1000 | 1070× | × | 14 | 350 | 880 | Φ | 1040 | 420 |

工(gong)作原理(lǐ):

Working principle

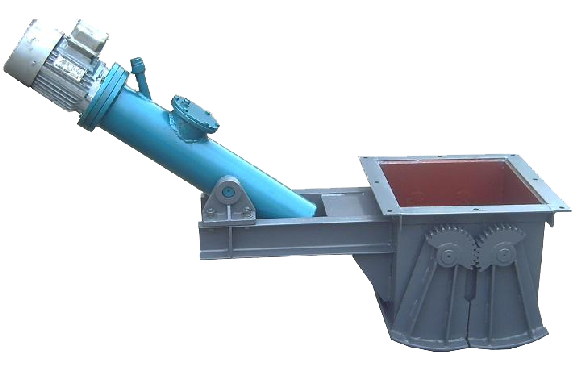

鄂式閘(zha)門由本(ben)體、扇形(xing)閘闆、軸(zhóu)、齒輪、密(mi)封副、執(zhi)行機構(gòu)📐等部件(jian)構成。手(shou)動或執(zhi)行機構(gou)推動搖(yao)杆,使齒(chi)輪帶動(dòng)扇形閘(zhá)闆🏃🏻沿軸(zhou)心旋轉(zhuan),使兩個(gè)扇形閘(zhá)闆向兩(liang)邊開啟(qi),物料随(suí)即下落(luo),待接料(liào)裝置滿(mǎn)載後,再(zài)由執行(háng)機構帶(dài)動搖杆(gan),使扇形(xing)閘闆👣複(fu)位,關閉(bi)截斷下(xià)落的物(wu)料。

The valve is made up of body, sector gate, axle, gear, sealing pairs and actuator etc. when the rocker is driven by hand or the actuator device, it will drive the gear to make the sector gate rotate and open, then material drop. When the loader is full, the actuator will drive the rocker to replace the sector gate, and then the falling material will be cut off.

使用(yòng)說明:

Usage explanation

l 安(an)裝時請(qing)注意閘(zhá)門本體(tǐ)上标明(míng)介質流(liu)向。兩法(fǎ)蘭連接(jiē)時♻️必需(xu)加密封(fēng)墊片,然(rán)後均勻(yún)鎖緊螺(luo)栓。

l 運行(hang)時請辨(biàn)清扇形(xing)閘闆開(kai)關方向(xiang),執行機(ji)構請正(zheng)确接線(xian)。

l 運行時(shi)請定期(qī)給各傳(chuán)動部位(wèi)加潤滑(hua)油。

l Pay attention to the flow direction of medium marked on the body. Add the sealed shim between the two flanges and then screw down the bolt.

l Add lubricant to the transmission parts regularly as it runs.

›